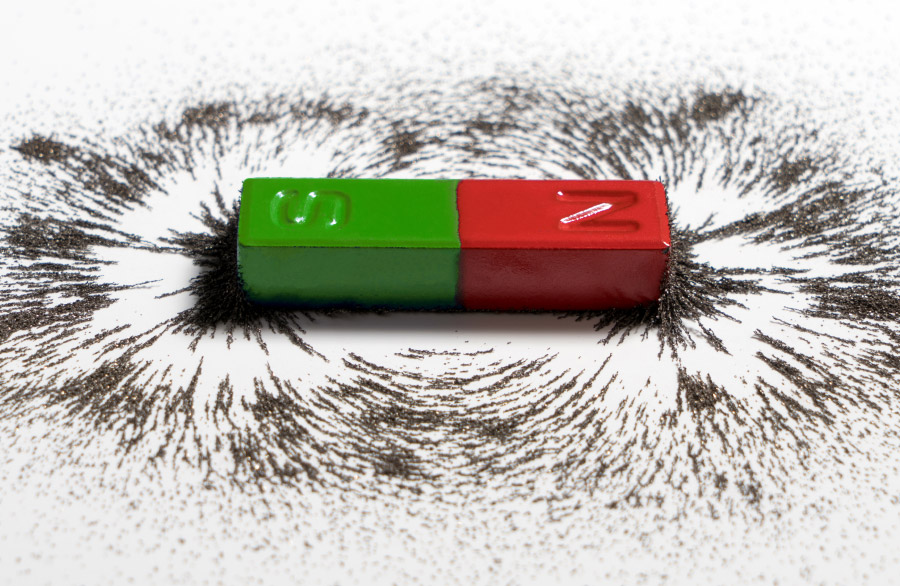

For over 90 years, Maurer Magnetic has been working in the field of magnet technology with permanent magnets, permanent magnet systems and solutions for measuring magnetism. In addition, it has also been dealing with new, groundbreaking developments in the field of demagnetization of ferromagnetic materials for several years.

Find out more about the technology of the magnets, or about our permanent magnet stock program.

The new Maurer Degaussing® demagnetization technology introduced at the beginning of the 2000s can reliably and efficiently perform tasks that were previously considered impossible. Here you can learn more about the technology and our product portfolio.

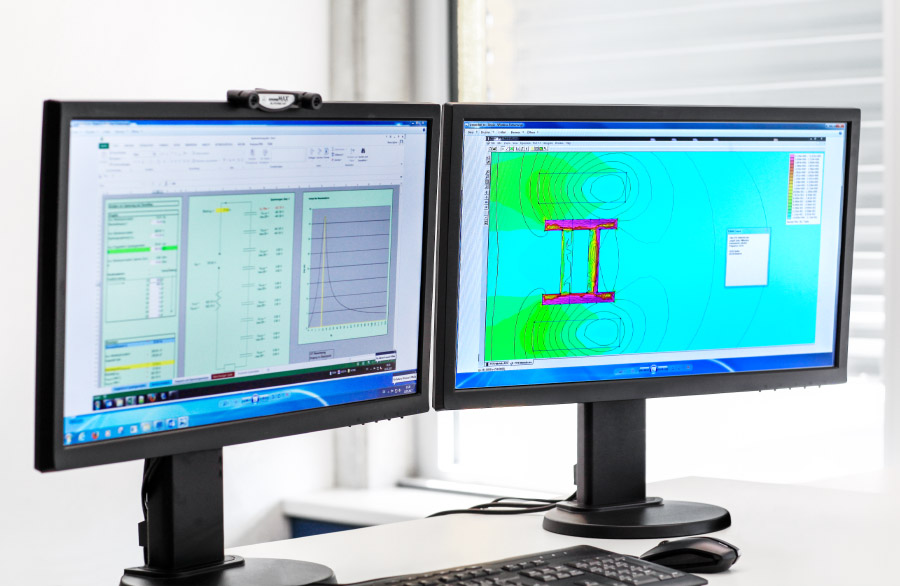

In order to be able to measure limit values (Gauss, mT or A / cm) it is not only necessary to have a precise measuring device. Maurer Magnetic has also opened a new chapter in the reproducibility of measuring residual magnetism. Here you will learn how to correctly measure residual magnetism.

Knowledge is the key to success!

Benefit from our many years of extensive knowledge about magnetism. We are pleased to share our know-how with you.

The right choice of magnet material, magnetisation type and magnet system is the basis for an optimal, customer-oriented solution.

The internationally tested new demagnetization approaches have been proven to exceed by far the methods used up to now, such as low-frequency generator, yoke and tunnel coils, as well as direct current pulse technology. Absolute process reliability and productivity is guaranteed, even below the level of the earth’s magnetic field.

Maurer Magnetic manufactures specialized equipment designed to meet the need for measuring residual magnetism. Standards for measuring residual magnetism have yet to be established worldwide. Thanks to its accuracy and reproducibility, Maurer Magnetic sets a new standard, which has already been established as the company standard in countless industrial companies.