Overview of the different demagnetization methods of Maurer Magnetic

Background story on the origin of the Maurer Degaussing® process

In 2001, at the request of a major Japanese manufacturer, we developed the “Maurer-Degaussing®” process for its novel series production of TV picture tubes with electron beam. None of the worldwide established suppliers of demagnetization processes dared to take on this task, which required new standards in demagnetization quality and process reliability in fully automated production. By using the latest power electronics, innovative ideas and many years of experience in the field of magnetism, we achieved this goal after only a one-year development phase. The result is the Maurer Degaussing® pulse process. The Maurer Degaussing technology is now internationally protected by several patents.

Based on this demagnetizing process, we offer international customers an extensive product range for the demagnetizing of ferromagnetic components, geared to the processing industry.

Fully automatic and thoroughly demagnetized within seconds – The Maurer Degaussing® method is suitable for demagnetizing in automated production processes as well as for manual operation. The controlled course of the alternating field, high productivity and complete reproducibility make Maurer Degaussing® ideal for industrial applications.

Maurer Degaussing® technology

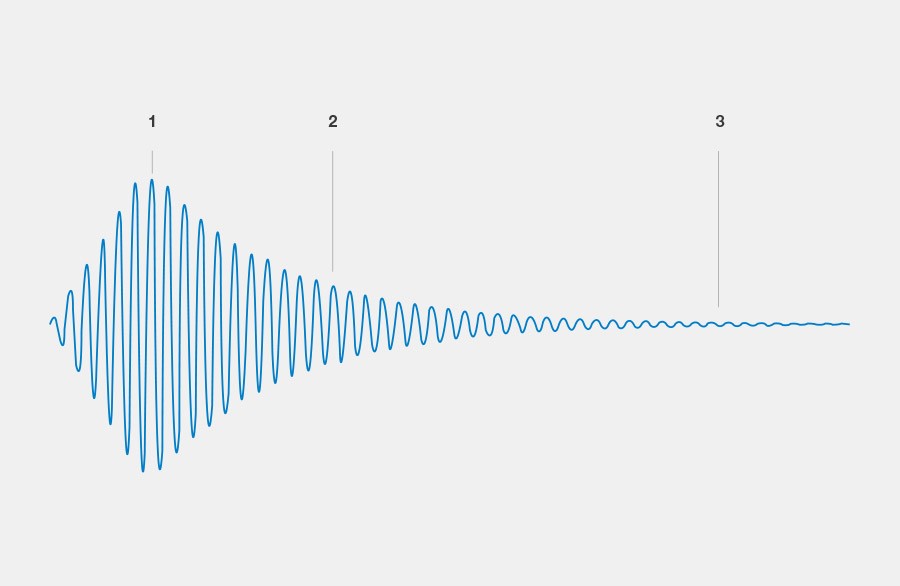

The Maurer Degaussing® process works with pulse demagnetization patented by Maurer. The intensity, amount and precision of the polarity reversals, and the frequency are implemented in an optimum manner by the Maurer-Degaussing® procedure. This package enables demagnetisation that cannot be performed with conventional methods:

- Short-term high magnetic field strength

- High number of monotonically decreasing vibrations

- Run-out exactly to zero magnetic field

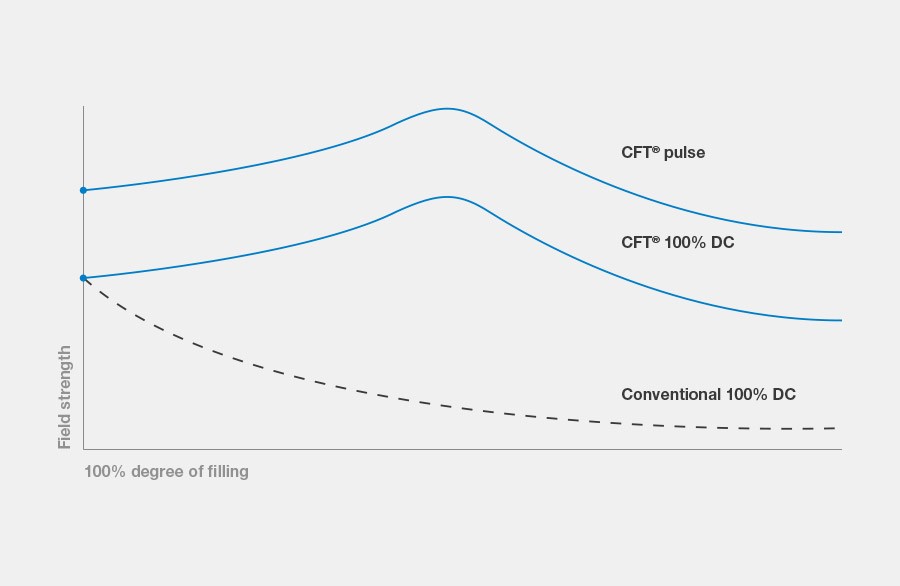

CFT® – Constant Field Technology

The patented CFT® (Constant Field Technology) keeps the magnetic field consistently high at the productive frequency regardless of the coil fill level.

The power is increased further in pulse mode.

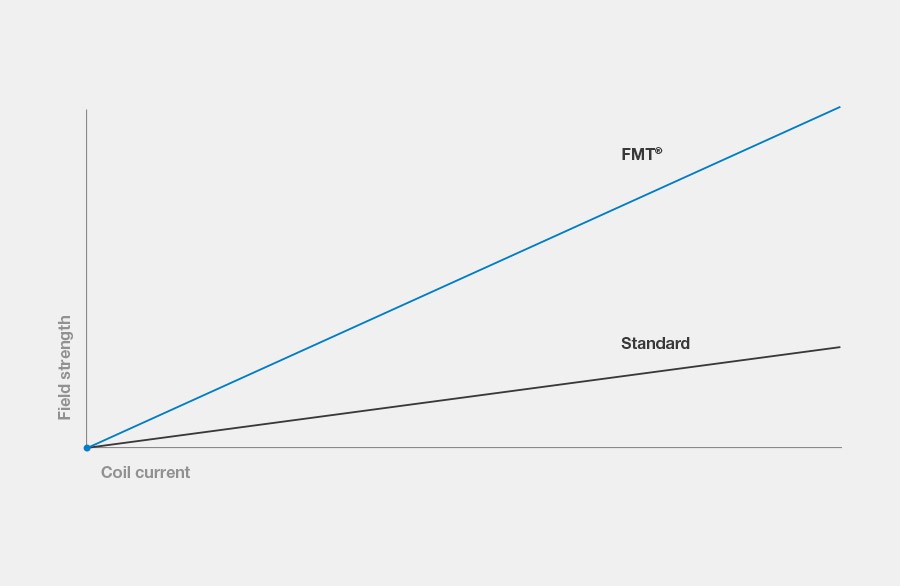

FMT® – Field Multiplicator Technology

The efficiency of the demagnetising process is implemented directly and used to the full with this technology. The electrical switching used to generate the high field multiplies the current that is fed in and therefore provides high demagnetisation field power. The FMT® (Field Multiplicator Technology) solves this problem and enables higher field strengths while keeping the electrical connection power lower at the same time.

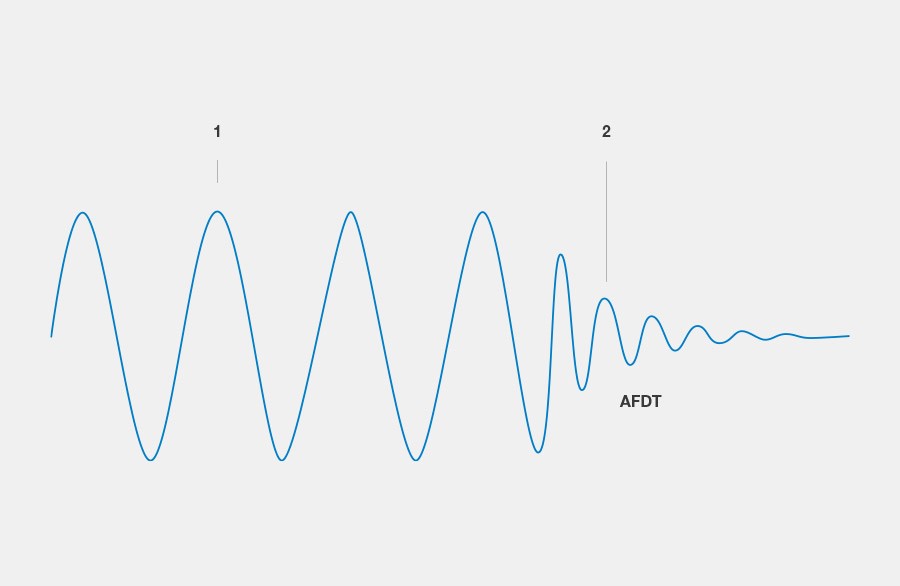

AFDT – Automatic-Field-Decline-Technology

When the device gets switched off, the alternating magnetic field will not be switched off immediately (in worst case at the highest point of an amplitude). AFDT continously reduces the magnetic field by decreasing amplitudes. This function delivers the following benefits to our customers:

- Demagnetize in one pass

- Automatic oscillation when switching off